Vibro Membrane Filtration (VMF) Products

From lab scale to production, we serve you all the way

Vibro-Lab Series

Simplyfying process development

Vibro-Lab35P

Designed for initial process development and membrane screening, the Vibro-Lab35P offers unprecedented flexibility and ease of use. As the technology is directly scalable from laboratory units to industrial units, the Vibro-Lab35P enables the user to simulate industrial processes on volumes as low as 20 mL.

The Vibro-Lab35P membrane cartridge contains 35 cm² of membrane surface area.

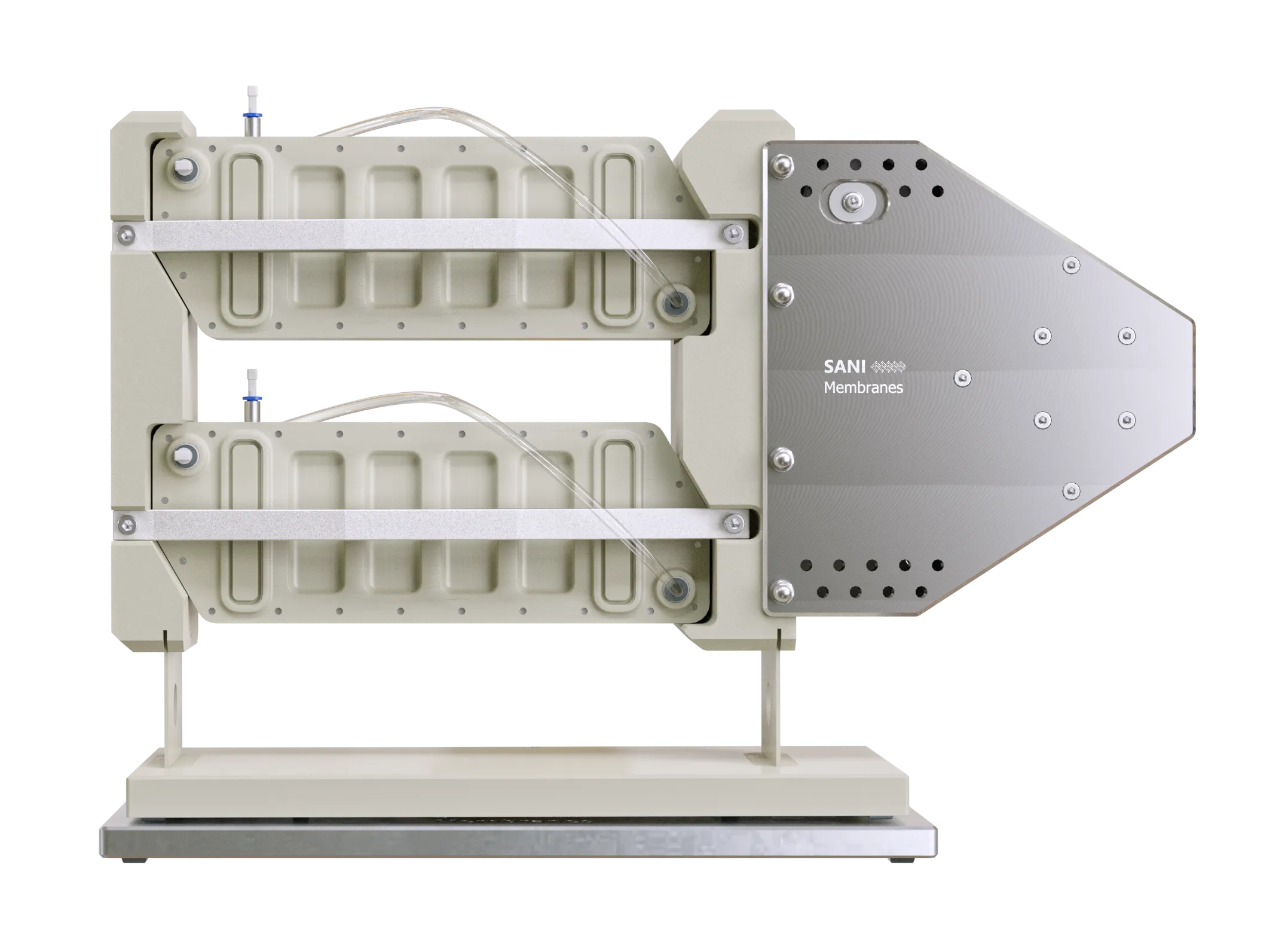

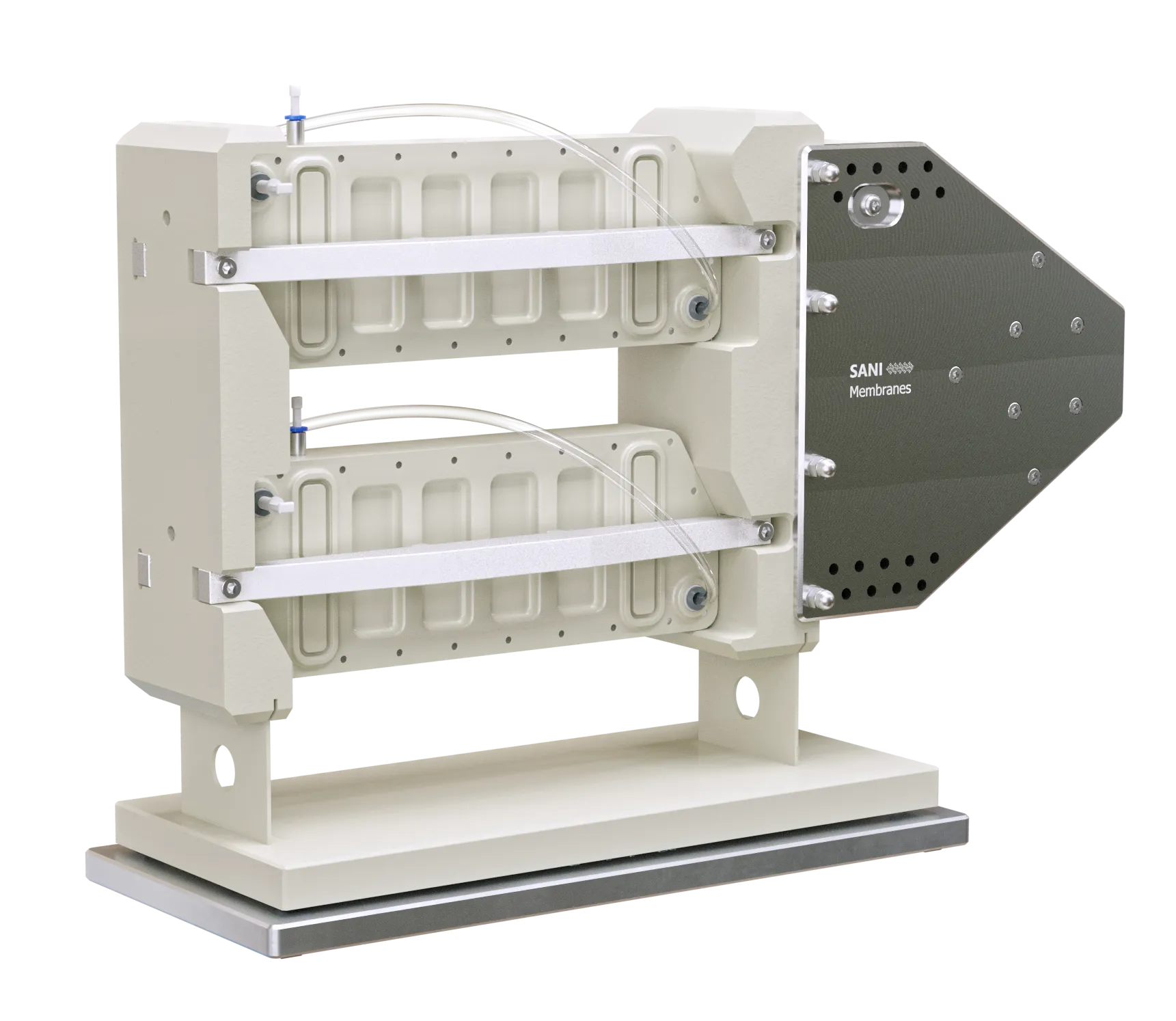

Vibro-Lab280

The Vibro-Lab280 is unique in its ability to fit multiple cartridges, enabling you to use different membranes on the same unit simultaneously. The size of the Vibro-Lab280, with an ideal process volume of 100 – 4,000 mL, makes it ideal for process development, working with small bioreactors and everything in between.

The Vibro-Lab280 contains 2 cartridges of 280 cm² membrane surface area, with the ability to substitute one of the cartridges with a dummy cartridge.

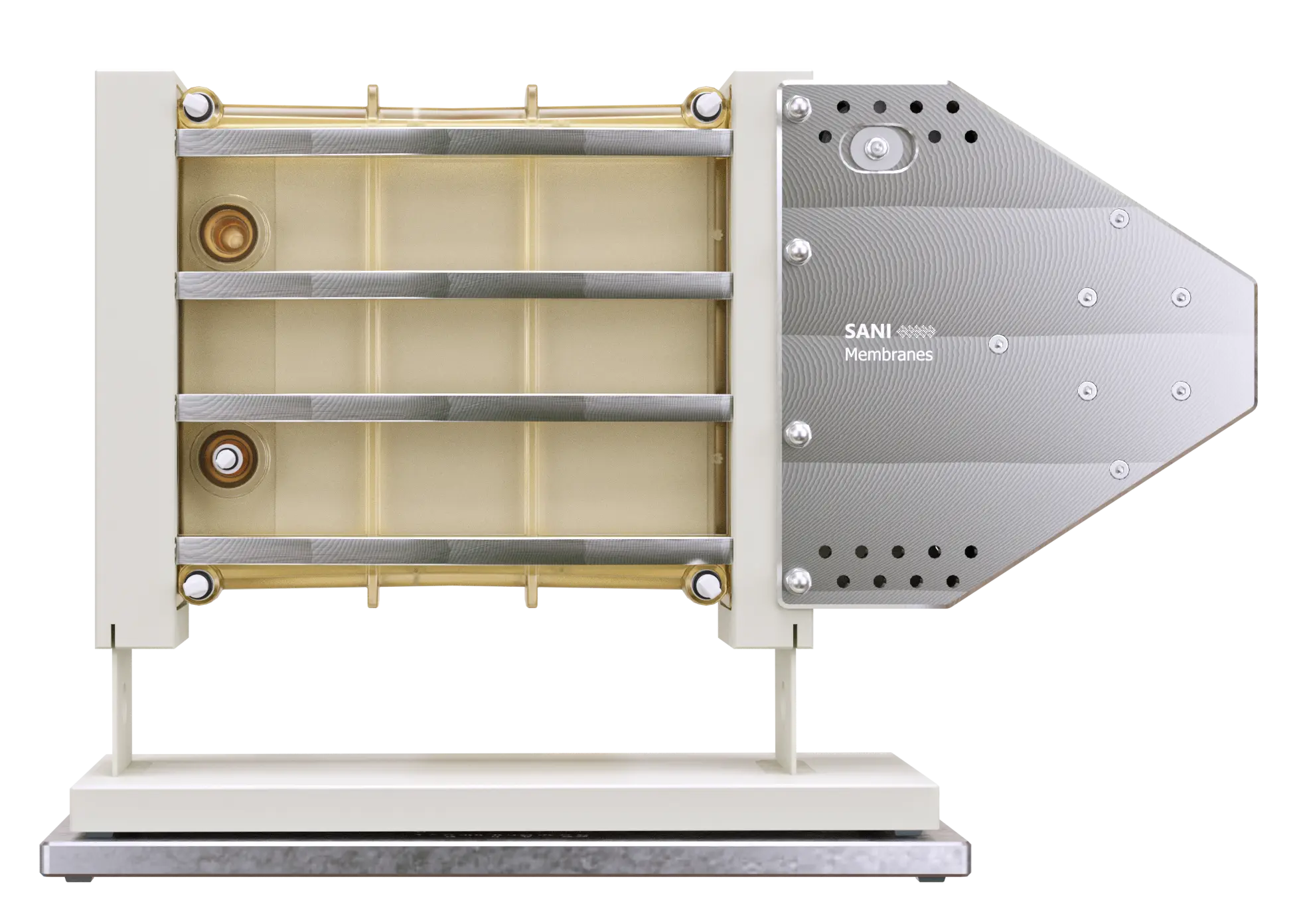

Vibro-Lab3500

With its see-through housing, it is possible to observe the membrane area during process and cleaning steps. The Vibro-Lab3500 is also the largest of our benchtop filtration units, enabling the user to manage relatively large amounts of media in a simple and user-friendly manner.

The Vibro-Lab3500 contains 3500 cm² of membrane surface area

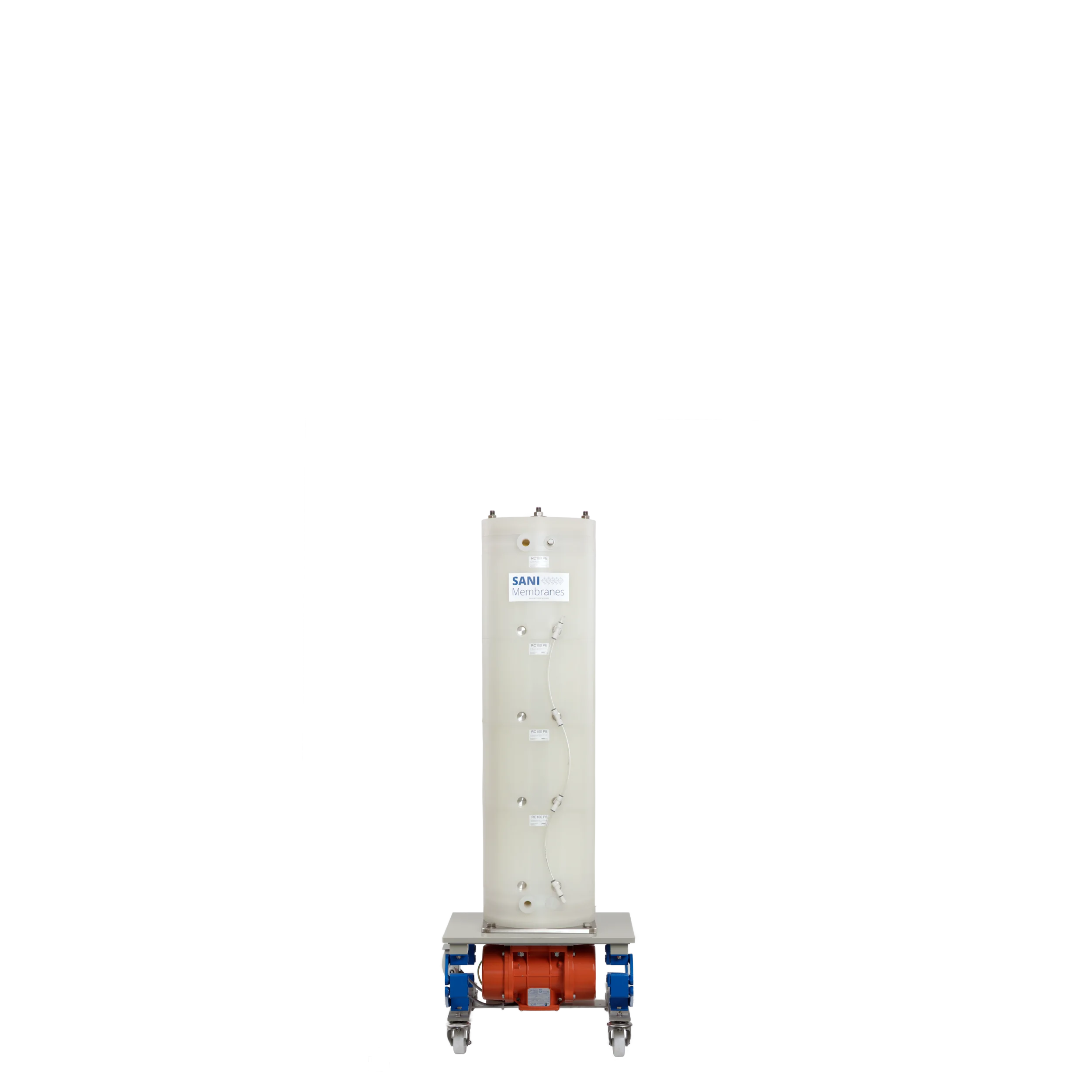

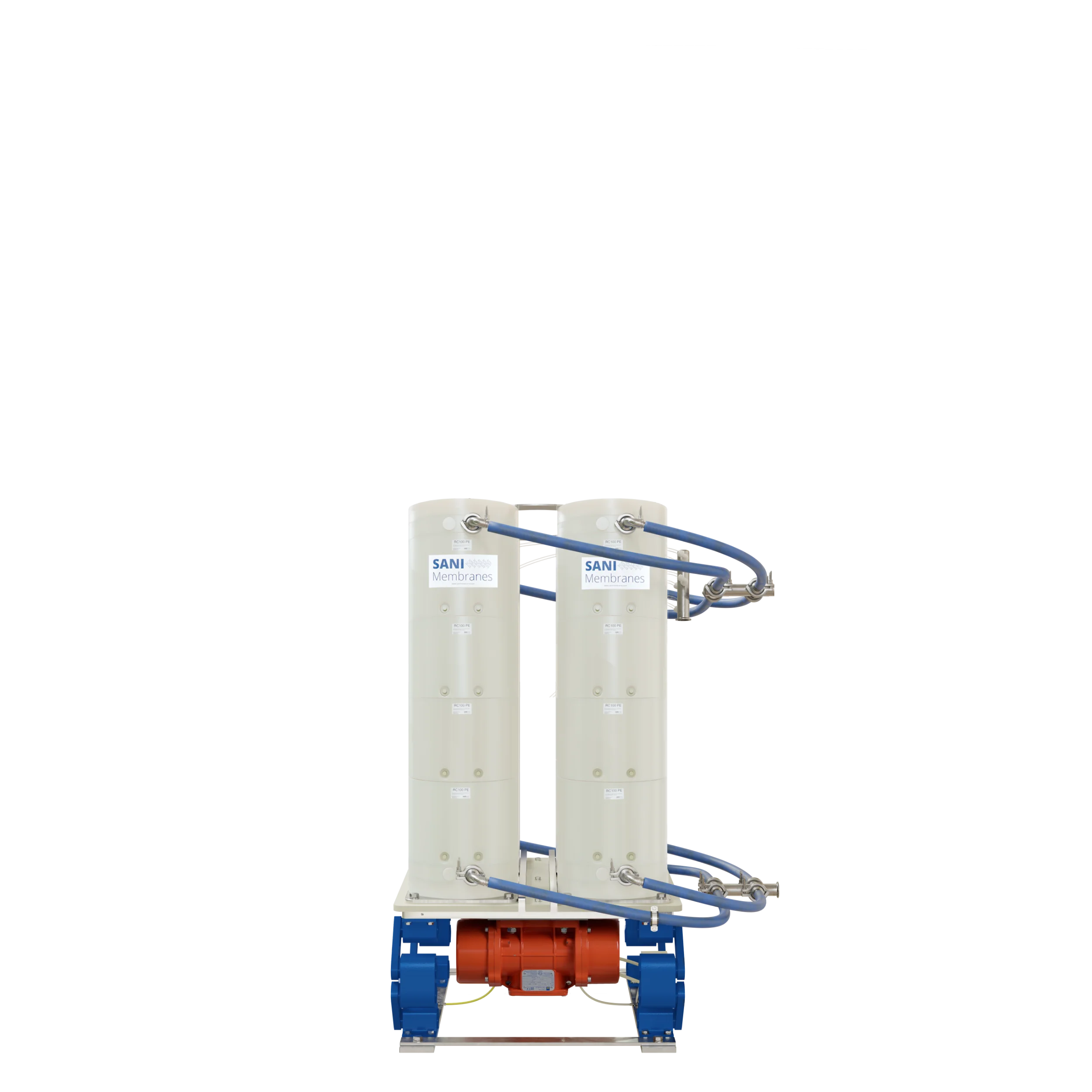

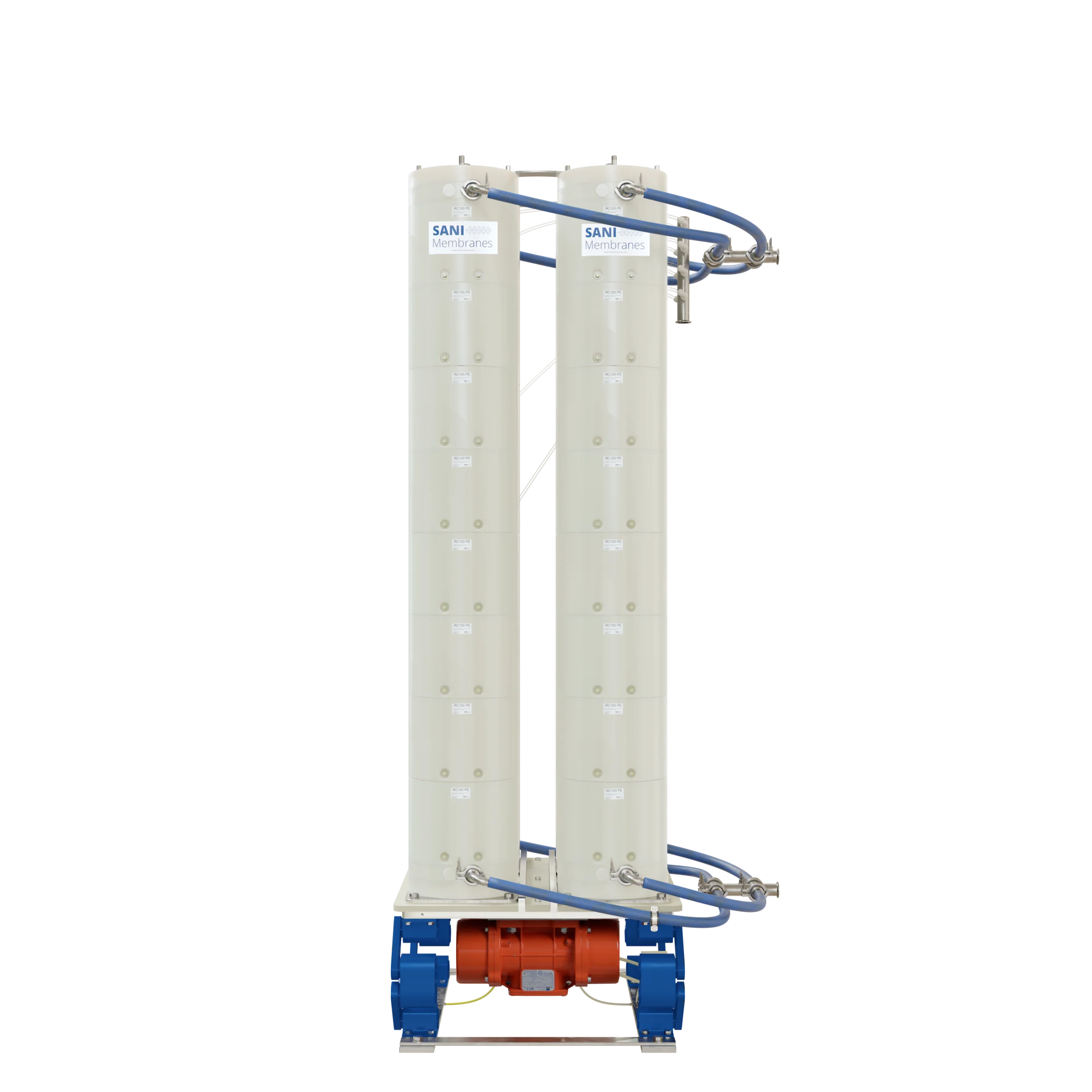

Vibro-I Series

All units in the Vibro-I range use the same stackable 2.5 m² membrane module. For pilot-scale and small-scale production, units with a surface area of 2.5 – 10 m² can be used. These units are designed and targeted for industrial applications, have a small footprint, are mobile, simple to use and can easily be set up next to an existing process line.

For further scale up to industrial plants, Vibro-I units with membrane surfaces of 20, 40, 80 m² are available.

The membrane module can be fitted with a wide selection of micro- and ultrafiltration membranes that can easily be exchanged.

For installations larger than 80 m², multiple units can be connected in parallel or serial configuration

Feed systems

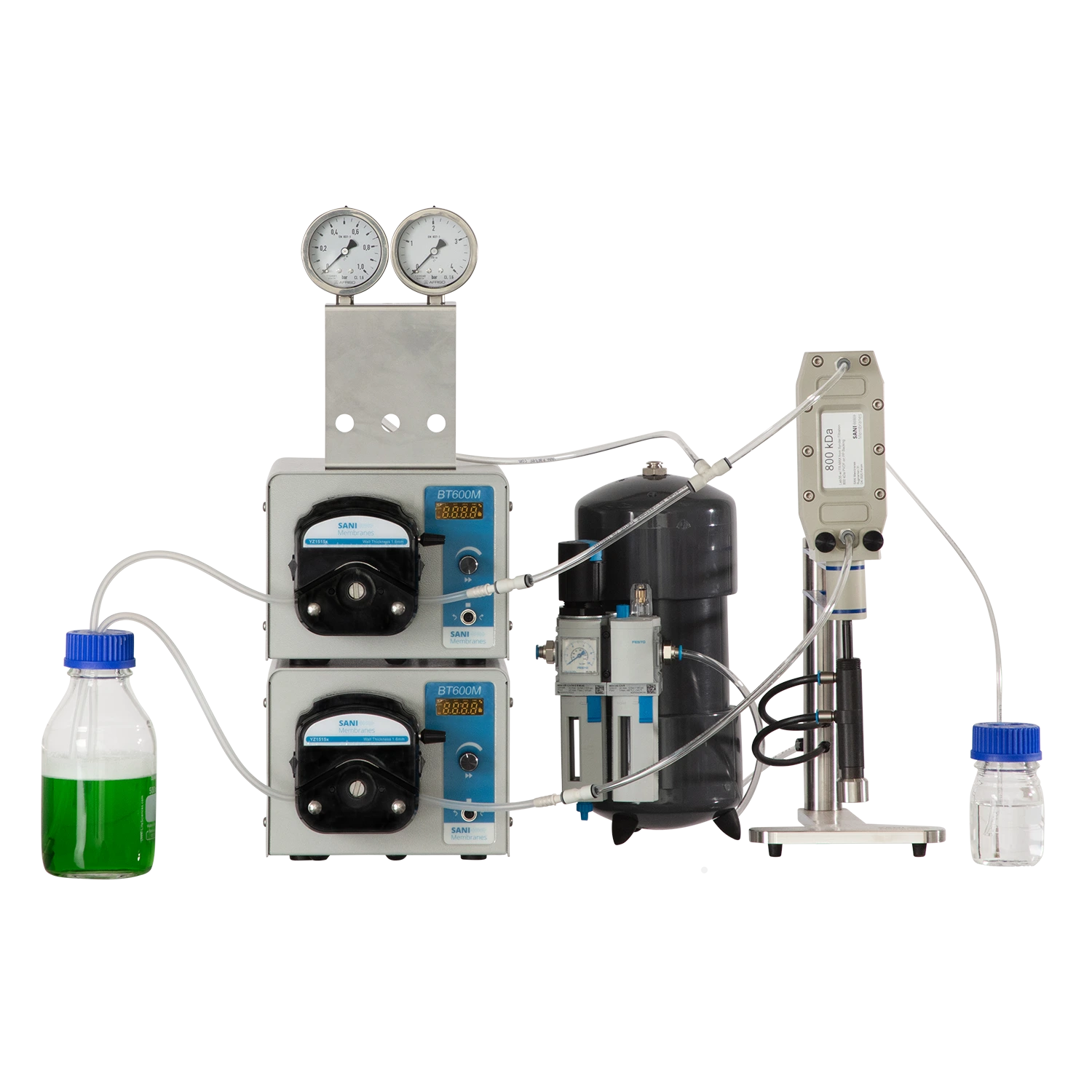

Vibro-I Pilot

The Vibro-I Pilot system offers complete process control and can be fitted with a variety of options to fit your individual needs. The system can easily be connected to Vibro-I units from 2.5 – 10 m².

Options:

– Mixflow measuresment and data logging

– Permeate flow and pressure measurement and data logging

– Retentate flow measurement and data logging

– Tubular heatexchanger for cooling / heating w/o controls

Membrane filtration systems with a membrane surface exceeding 1 m² is subject to the regulation on the Control of Certain Biological Agents, Carriers, and Related Materials (EU No. 981 of 15/10/2009). This means that an export permit is required for certain countries, and registration with CBB (Danish Center for Biosecurity & Preparedness) is necessary in others.

Contact us

Describe the nature of your inquiry in the form and fill out your contact information and we will respond to you as soon as possible.

Help and support

Do you need access to the latest product manuals or product specifications?

Send A Message

When filling in the data form, you accept receiving digital communications from SANI Membranes. In order to withdraw your acceptance, please contact info@sanimembranes.com