Vibro Membrane Filtration (VMF) Products

From lab scale to production, we serve you all the way

Vibro-Lab Series

Simplyfying process development

Vibro-Lab35P

Designed for initial process development and membrane screening, the Vibro-Lab35P offers unprecedented flexibility and ease of use. As the technology is directly scalable from laboratory units to industrial units, the Vibro-Lab35P enables the user to simulate industrial processes on volumes as low as 20 mL.

The Vibro-Lab35P membrane cartridge contains 35 cm² of membrane surface area.

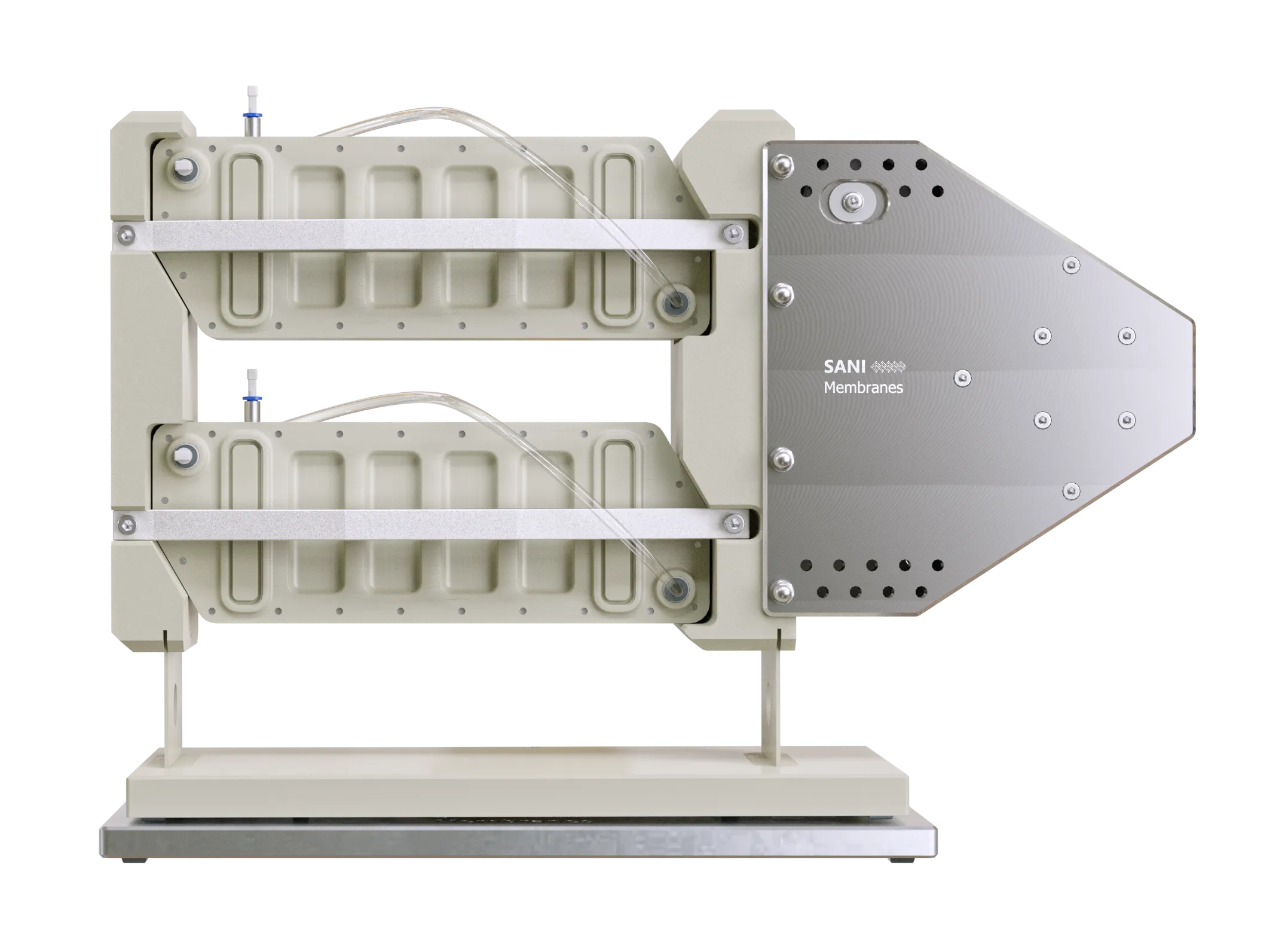

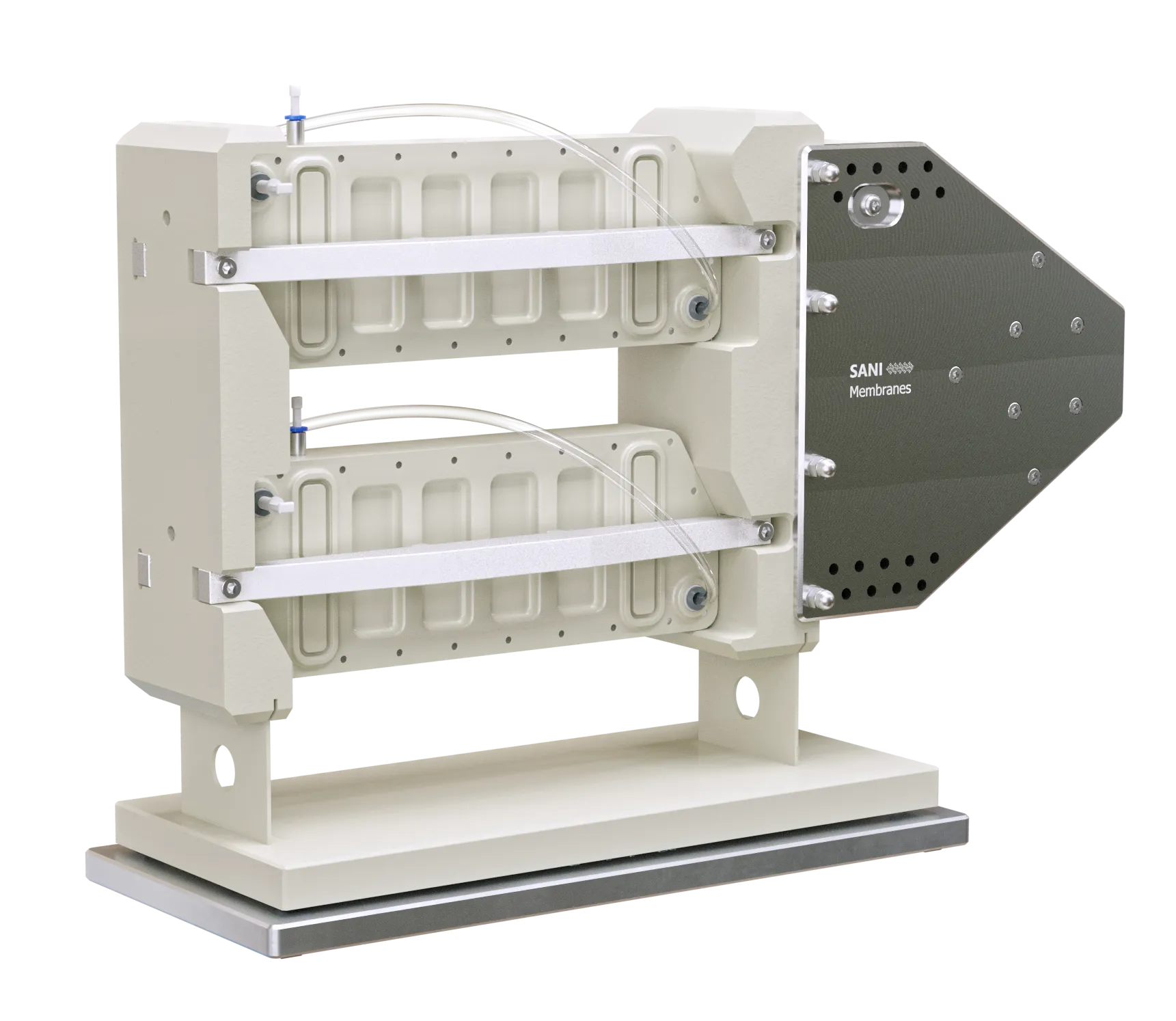

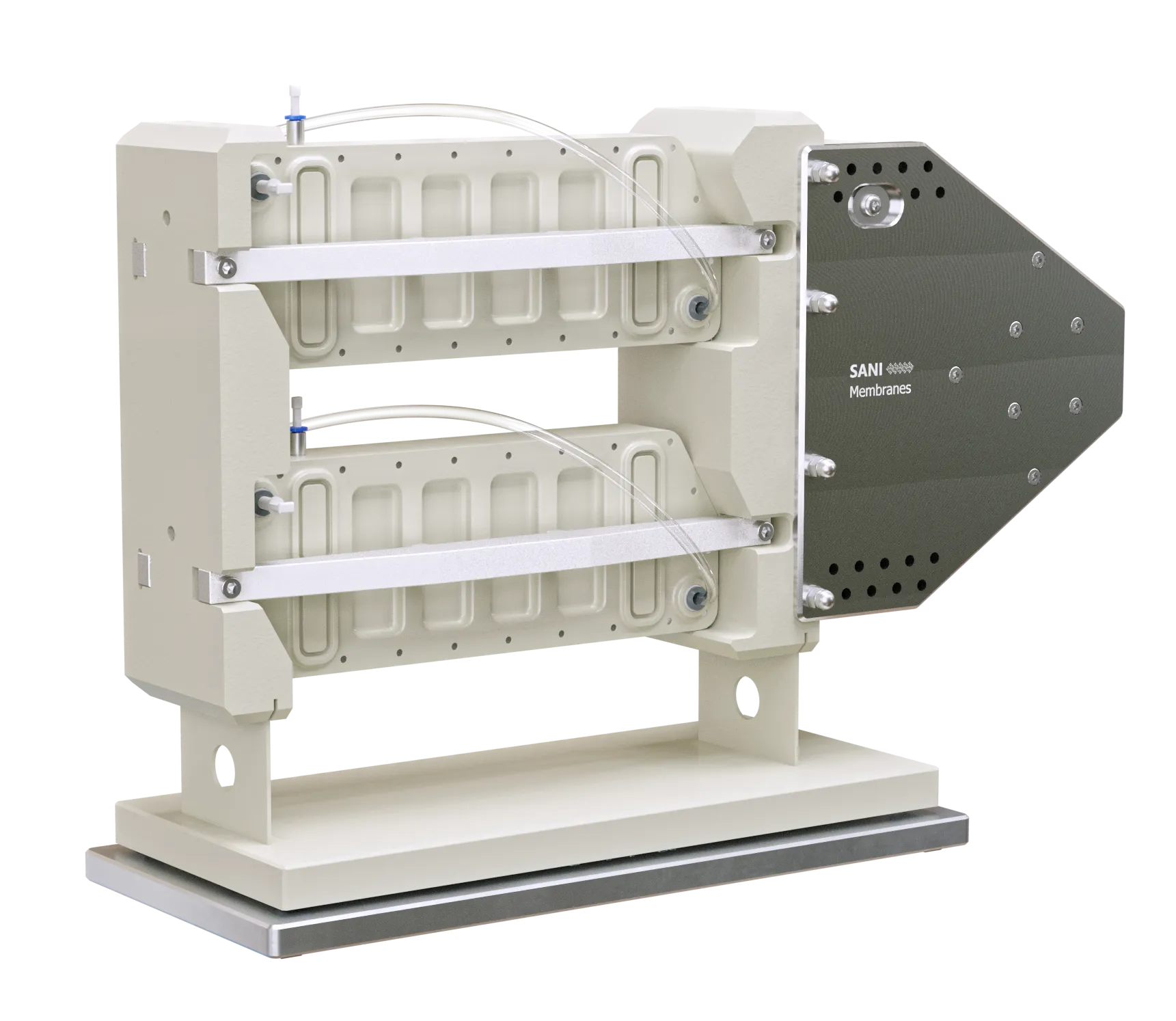

Vibro-Lab280

The Vibro-Lab280 is unique in its ability to fit multiple cartridges, enabling you to use different membranes on the same unit simultaneously. The size of the Vibro-Lab280, with an ideal process volume of 100 – 4,000 mL, makes it ideal for process development, working with small bioreactors and everything in between.

The Vibro-Lab280 contains 2 cartridges of 280 cm² membrane surface area, with the ability to substitute one of the cartridges with a dummy cartridge.

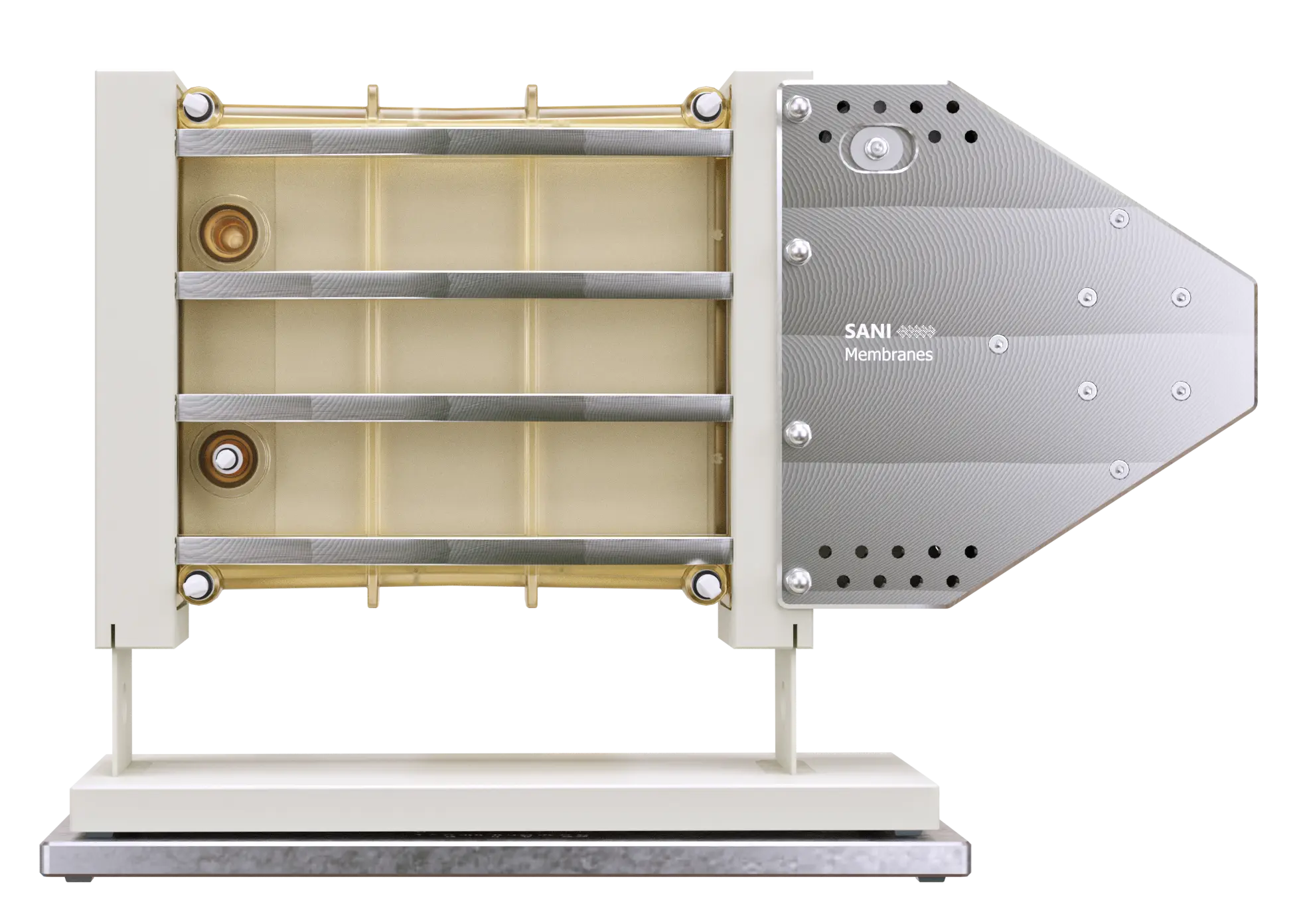

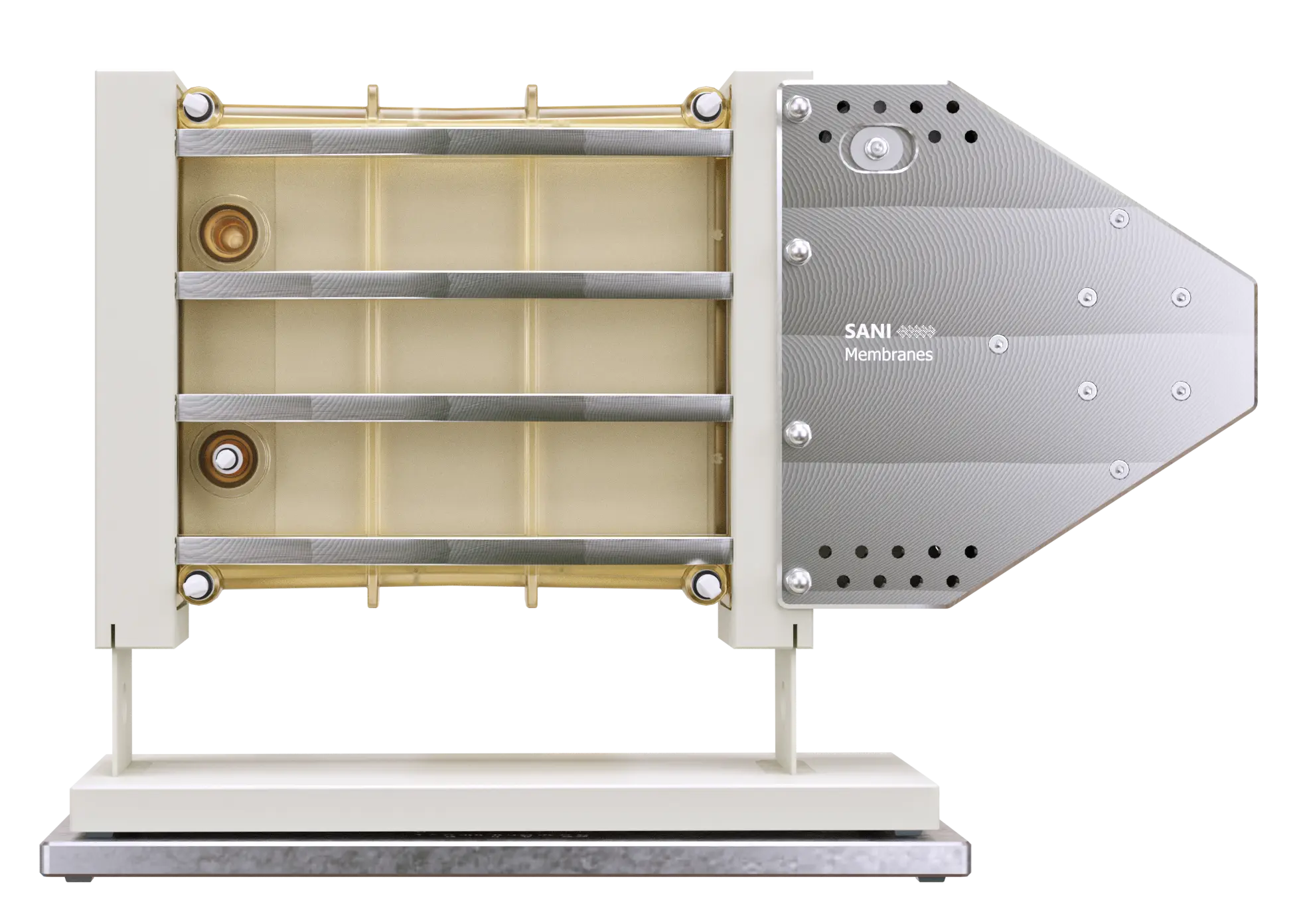

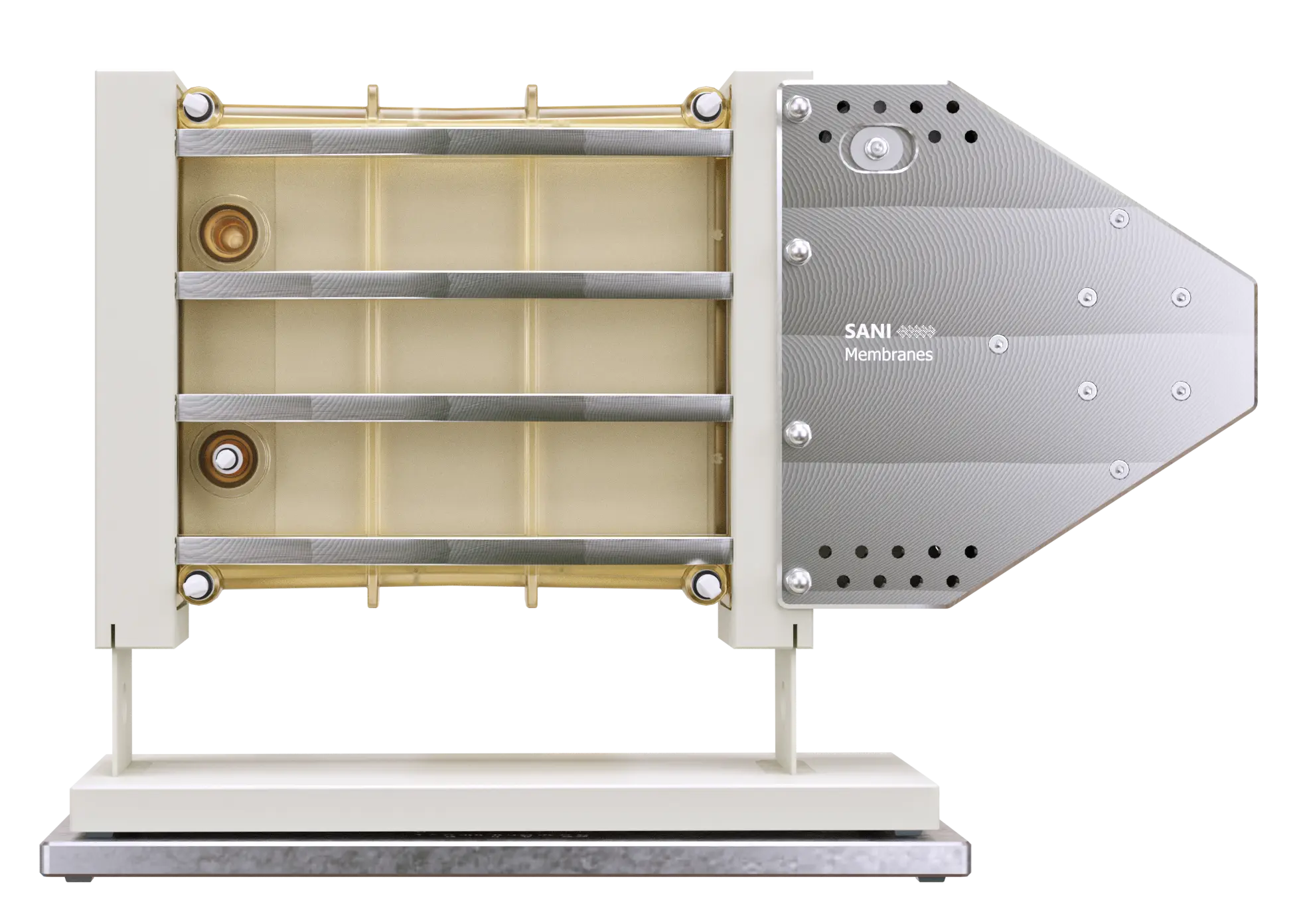

Vibro-Lab3500

With its see-through housing, it is possible to observe the membrane area during process and cleaning steps. The Vibro-Lab3500 is also the largest of our benchtop filtration units, enabling the user to manage relatively large amounts of media in a simple and user-friendly manner.

The Vibro-Lab3500 contains 3500 cm² of membrane surface area

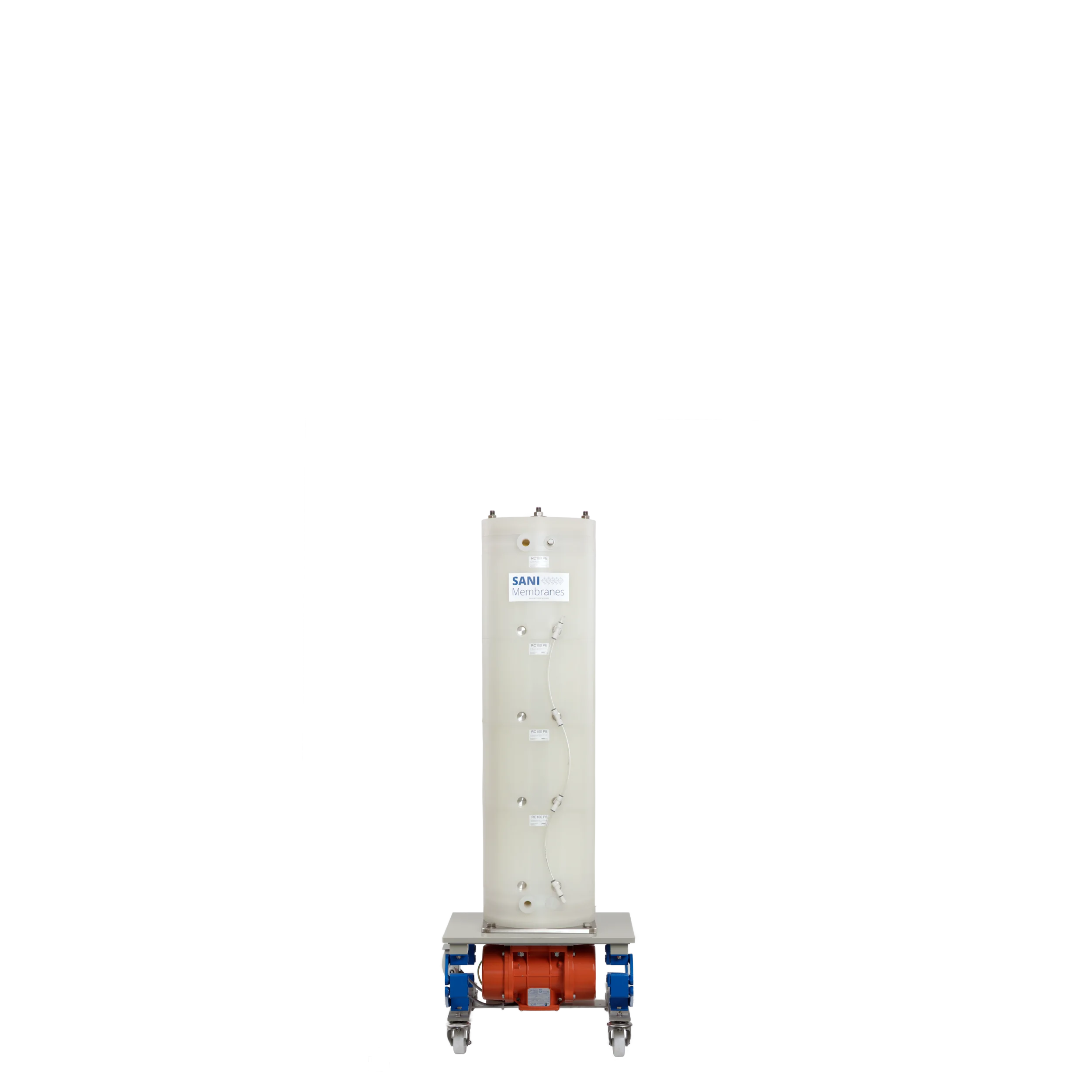

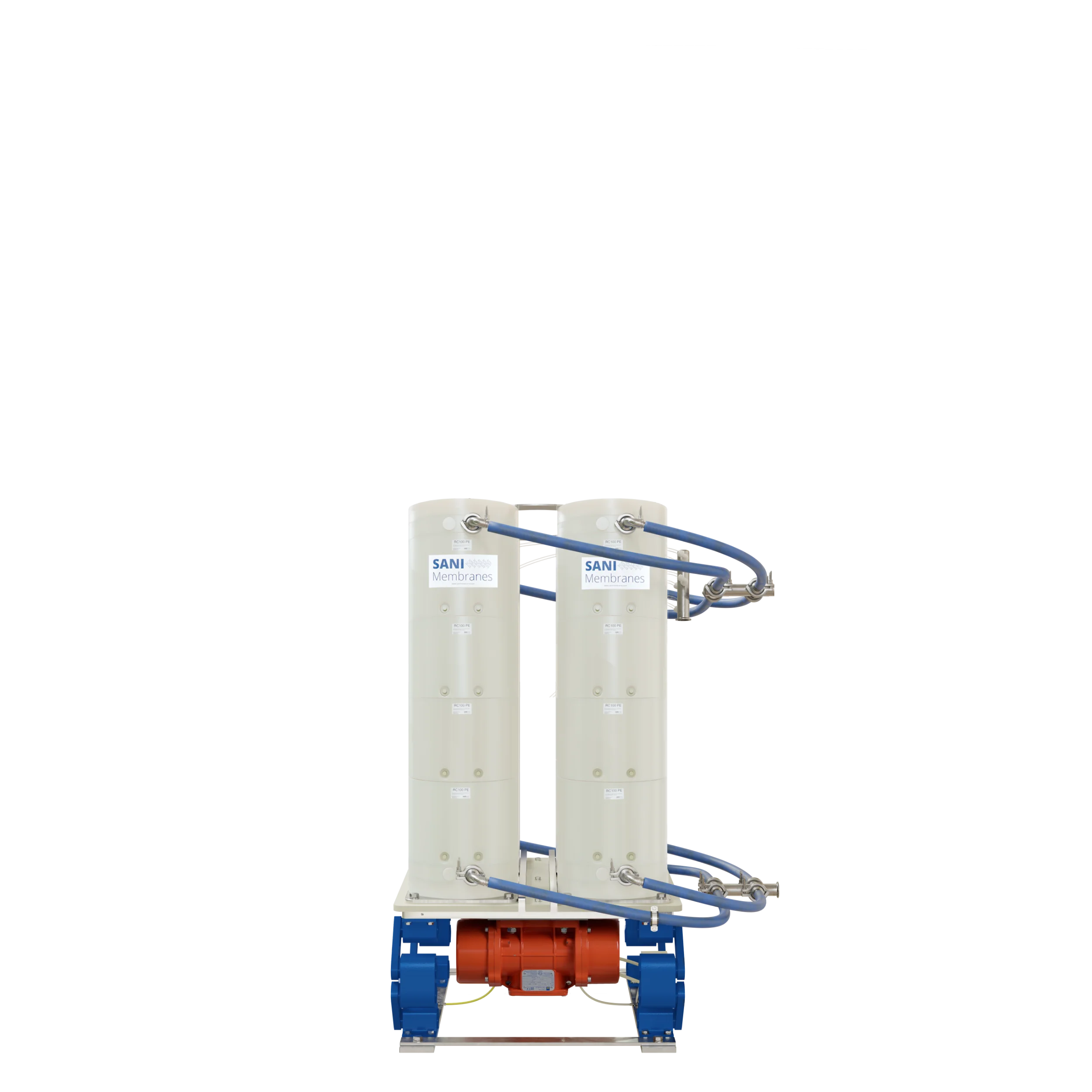

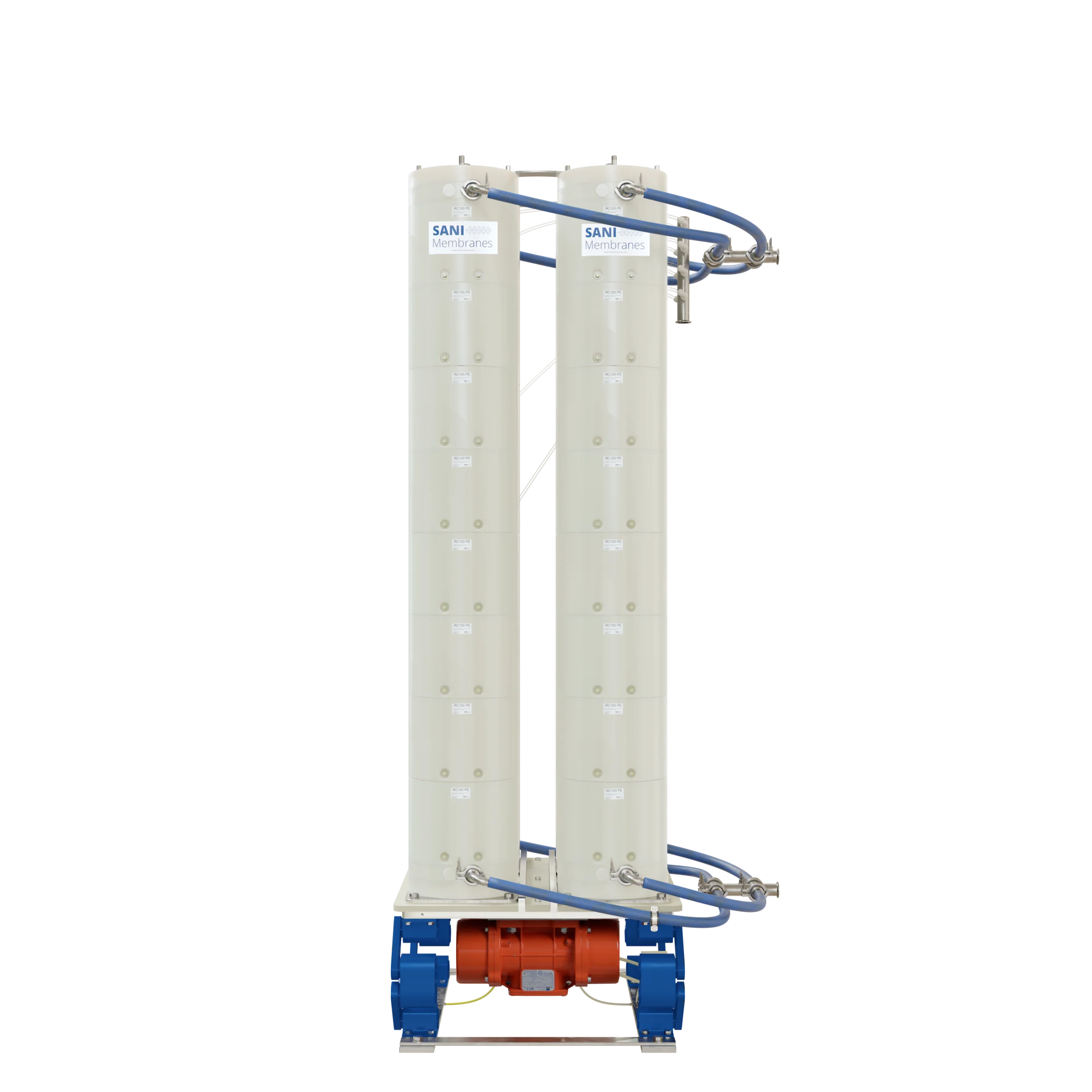

Vibro-I Series

All units in the Vibro-I range use the same stackable 2.5 m² membrane module. For pilot-scale and small-scale production, units with a surface area of 2.5 – 10 m² can be used. These units are designed and targeted for industrial applications, have a small footprint, are mobile, simple to use and can easily be set up next to an existing process line.

For further scale up to industrial plants, Vibro-I units with membrane surfaces of 20, 40, 80 m² are available.

The membrane module can be fitted with a wide selection of micro- and ultrafiltration membranes that can easily be exchanged.

For installations larger than 80 m², multiple units can be connected in parallel or serial configuration

Feed systems

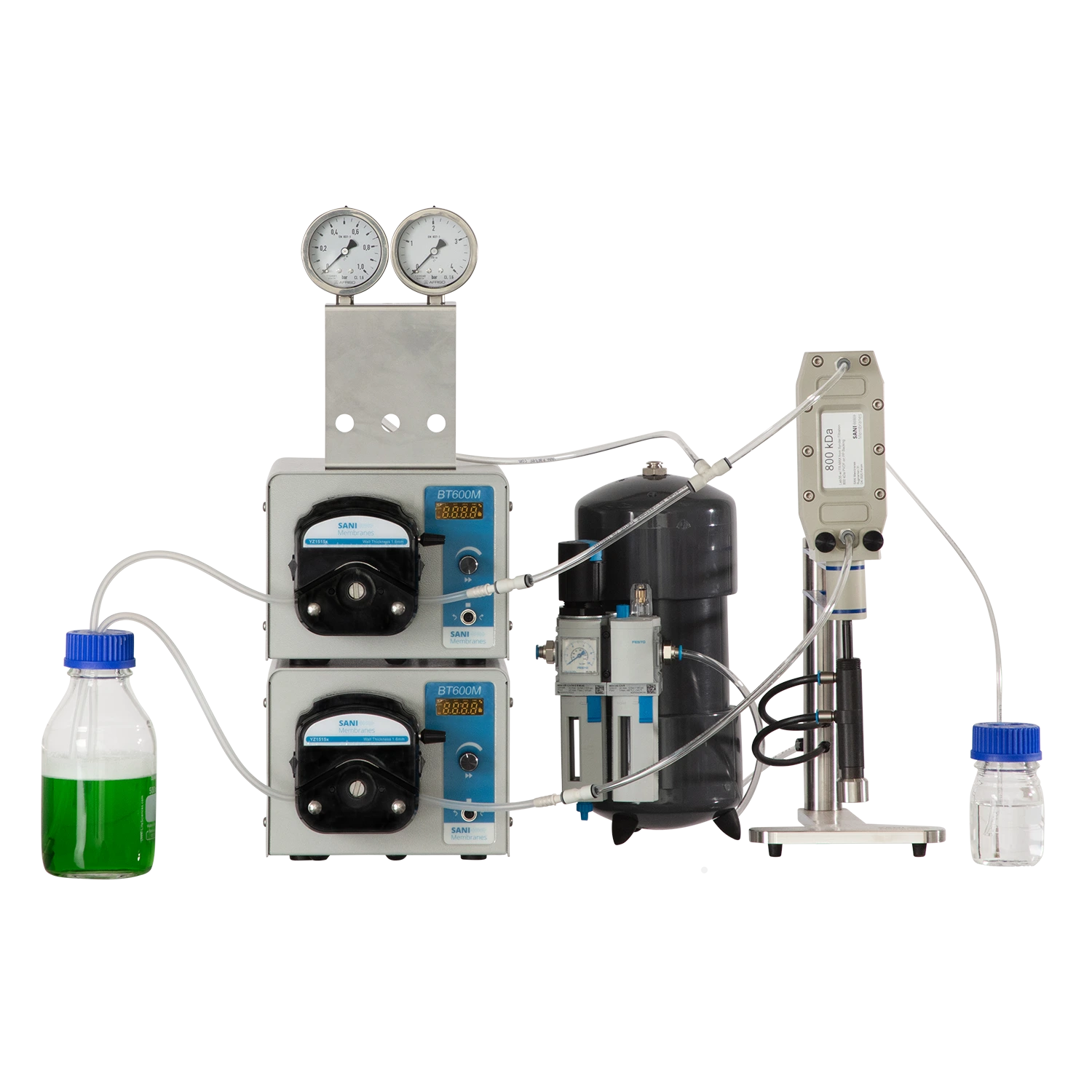

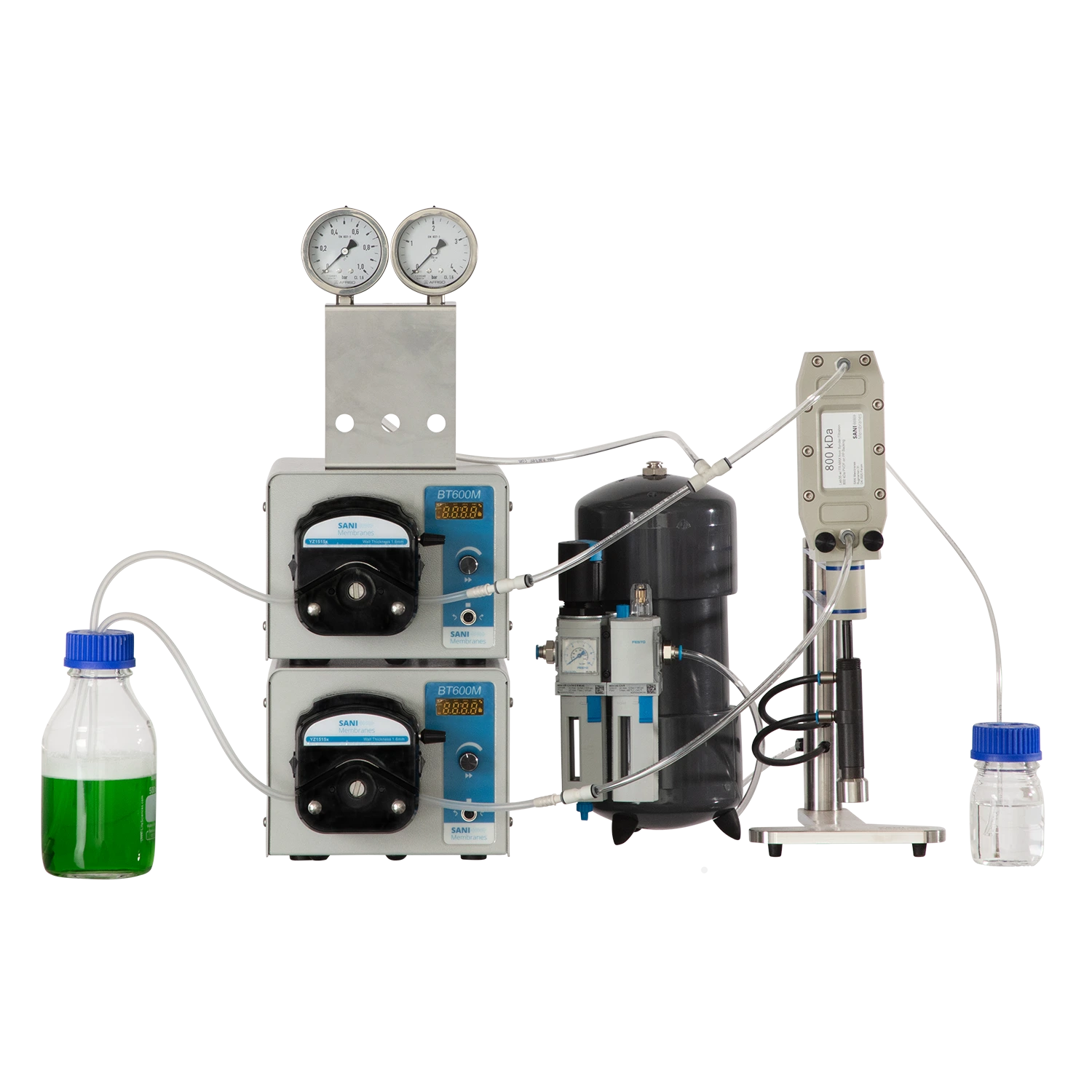

Vibro-I Pilot

The Vibro-I Pilot system offers complete process control and can be fitted with a variety of options to fit your individual needs. The system can easily be connected to Vibro-I units from 2.5 – 10 m².

Options:

– Mixflow measuresment and data logging

– Permeate flow and pressure measurement and data logging

. Retentate flow measurement and data logging

– Tubular heatexchanger for cooling / heating w/o controls

Membrane filtration systems with a membrane surface exceeding 1 m² is subject to the regulation on the Control of Certain Biological Agents, Carriers, and Related Materials (EU No. 981 of 15/10/2009). This means that an export permit is required for certain countries, and registration with CBB (Danish Center for Biosecurity & Preparedness) is necessary in others.