What is ultrafiltration?

Ultrafiltration (UF) is a pressure driven separation process which is widely used for retaining particles larger than 1 kDa, such as peptides, enzymes, antibodies and proteins. It is typically employed for concentration, fractionation, purification and recovery of target molecules.. The applications of ultrafiltration spans various industries, including biotech, pharmaceutical, food, beverages, algae, nano carbon materials, wastewater treatment and many more.

How ultrafiltration works

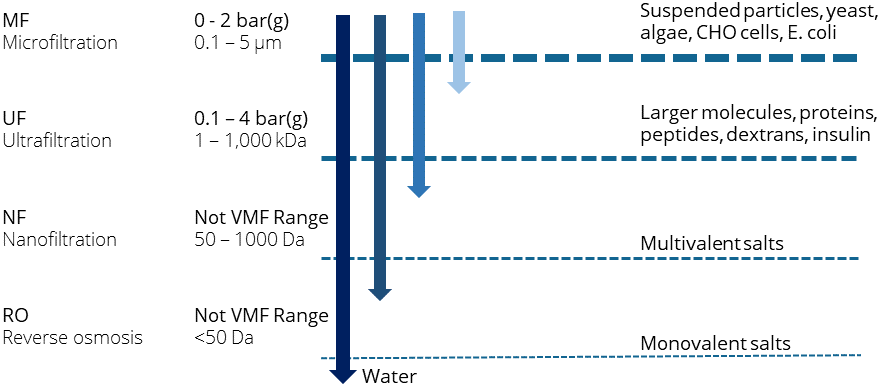

Ultrafiltration separates liquid into two streams: A permeate containing smaller molecules, and a retentate containing larger molecules. It works by passing liquid through a finely porous membrane, allowing smaller molecules, such as water, salts and small organic molecules to pass through while retaining larger molecules, e.g. proteins, viruses, bacteria, antibodies and colloids.

Similar to microfiltration, ultrafiltration is a pressure-driven process, with the driving force being the transmembrane pressure (TMP), which is the difference in pressure across the membrane. Ultrafiltration is however operated at a higher TMP than microfiltration.

Unlike microfiltration, which separates particles based on size, ultrafiltration determines a membrane’s ability to selectively separate molecules based on molecular weight cut-off (MWCO) and other factors, such as electrical affinity. MWCO is a loosely defined term generally taken to mean the molecular weight of the globular protein molecule that is 90% rejected by the membrane.

Vibro® Membrane Filtration (VMF) works by creating turbulence at the membrane surface, induced by vibrations. The turbulence minimizes fouling and concentration polarization, allowing for continuous operations, long operational intervals between need for CIP cleaning and a long membrane lifespan. By using vibrations to create turbulence on the membrane surface rather than relying high pump pressure, VMF enables a gentler process, reducing cell shear. This approach also allows for a uniform TMP, providing complete control over process parameters. The elimination of crossflow pumps also means that energy consumption is reduced by up to 95%, making VMF a highly efficient and sustainable ultrafiltration method.

Membrane filtration: Separation in sizes less than 5 µm

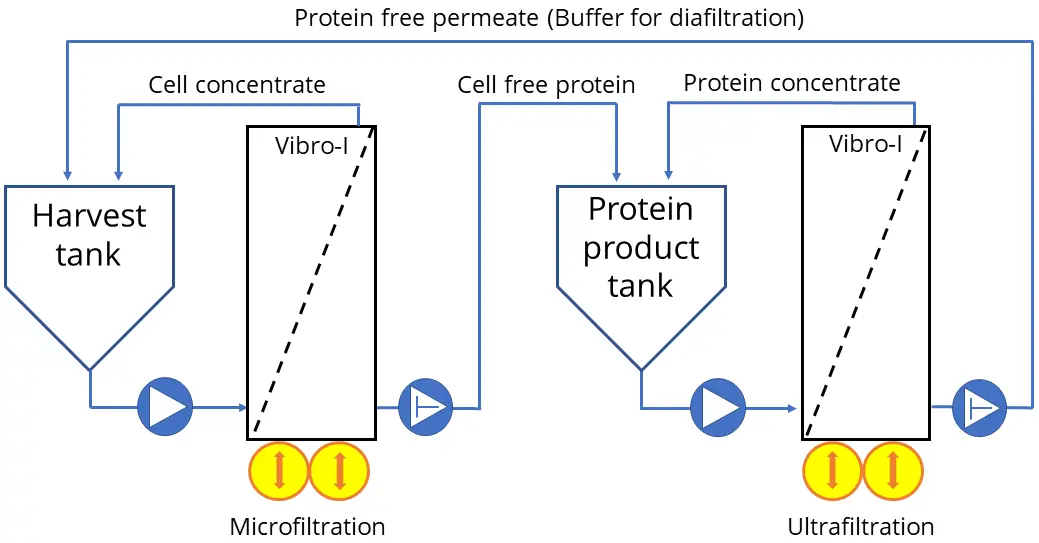

Application Example Microfiltration / Ultrafiltration:

Recovery and concentration of protein

Description:

In this example, VMF is applied for an extracellular protein process, where the fermentation broth is processed directly, and a concentrated protein is achieved.

The fermentation broth is processed in a Vibro® microfiltration unit, where the cells are separated from the proteins. The resulting concentrate (retentate) is returned to the harvest tank. The positive pump creates an ultralow TMP that prevents fouling from building up. This means that the Vibro® unit sustains an exceptionally high transmission of protein throughout the process. The cell free protein (permeate) from the Vibro® microfiltration unit, is transferred to the product tank.

From the product tank, the protein is gently concentrated in a Vibro® ultrafiltration unit, where the concentrate is returned to the product tank. A positive pump creates the TMP needed for the process and can return the protein free retentate to the harvest tank. In the harvest tank, the retentate is used as a diafiltration buffer, to wash the cells further, while keeping the cell concentration low and avoiding excess water consumption (closed loop).

When the fermentation broth is virtually free of protein, the Vibro® microfiltration unit is stopped, and the Vibro® ultrafiltration unit is run until the desired protein concentration is reached.

This setup makes it possible to achieve +95% recovery without using additional water or buffer for diafiltration.

In this setup, it is also possible to change buffer, adjust pH etc. during the process.

Applications of Ultrafiltration

Ultrafiltration Membranes

Contact us

Describe the nature of your inquiry in the form and fill out your contact information and we will respond to you as soon as possible.

Help and support

Do you need access to the latest product manuals or product specifications?

Send A Message

When filling in the data form, you accept receiving digital communications from SANI Membranes. In order to withdraw your acceptance, please contact info@sanimembranes.com