Biotech/Pharma

SANI Membranes is a trusted partner in filtration solutions for biotech and pharma industries

The Vibro® Technology makes it possible to optimize several separation processes within the Biotech and Pharma industry. With Vibro® filtration, you can replace centrifuges, depth filters, plate and frame systems and other separation techniques.

High Yield Recovery – increase of up to 25%

High Concentration, Viscosity and Solid Load – replace complex separators

Gentle Product handling – No pump No shear

Eliminating manual work – reusable microfiltration filters

Ideal Separation – better products, sharper cut-off

The Vibro® technology is typically used within the following separation steps:

Initial separation of cells/microbes and protein/API:

The Vibro® Technology makes it possible to process broth directly from the fermenter and achieve a high yield due to the low trans membrane pressure (TMP) which allows actual microfiltration.

- For Intracellular processes, the Vibro® Technology can achieve a high cell density due to the open design of the Free Flow Plates™

- For extracellular processes, the Vibro® Technology can achieve an extremely high recovery due to the ultralow TMP which makes it possible to control the fouling layer and achieve high transmissions of target compounds

Separation of cell debris and protein/API:

The Vibro® Technology makes it possible to do an efficient separation of cell debris (after cell lysis) and protein/API due to the ultralow and uniform TMP which makes actual microfiltration possible.

You can read more about using Vibro® filtration for biotech and pharma processing in the biotech/pharma presentation under downloads and presentations

Concentration of protein/API:

The Vibro® technology makes it possible to achieve a high concentration of protein/API due to the open and clean design of the Free Flow Plates™.

The Vibro® technology creates the following benefits

Reduced product shear:

With the Vibro® technology the cross flow pump is replaced by vibration which reduces product shear to a minimum

Reduced energy consumption:

With the Vibro® technology it is possible to reduce the energy consumption by up to 95% since the cross flow pump is redundant

Actual continuous microfiltration:

With the Vibro® technology it is possible to do actual microfiltration due to the low and uniform TMP

Improved separation:

With the Vibro® technology the separation is improved due to the uniform TMP which ensures that the membranes molecular weight cut off (MWCO) is the same on the entire membrane area – even for industrial plants

Industrial Example:

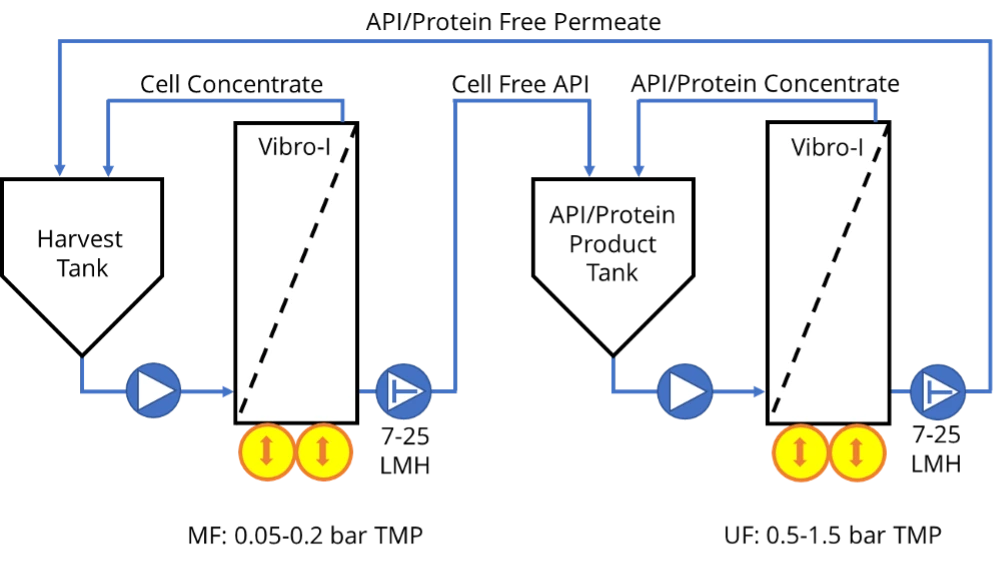

Simple Recovery and Concentration

The Vibro® Technology is in the following example applied for an extracellular API process where the fermentation broth is processed directly, and a concentrated API is achieved.

Description:

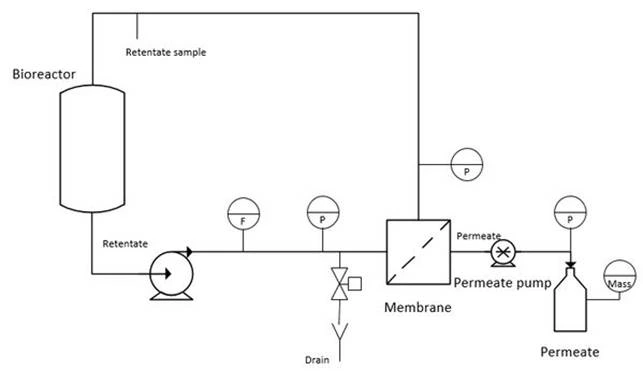

The fermentation broth is processed in a

Vibro-I microfiltration unit where the cells are separated from the API. The resulting cell concentrate is returned to the harvest tank. The positive pump creates an ultralow TMP that prevents fouling from building up and as a consequence a high transmission of API is maintained throughout the process. The cell free API from the Vibro-I microfiltration unit is transferred to the product tank.

From the product tank, the API is gently concentrated in a Vibro-I ultrafiltration unit where the concentrate is returned to the product tank. A positive pump creates the pressure needed for the process and can return the API free buffer to the harvest tank to wash the cells further, while keeping the cell concentration low.

When the fermentation broth is virtually API free, the Vibro-I microfiltration unit is stopped and the Vibro-I ultrafiltration unit is run until the API concentration target is reached.

It is also possible to change buffer, adjust pH etc. during the process.

The setup makes it possible to achieve up to 95% recovery without using additional liquid for diafiltration.

The system is simple to use and requires minimal control.

Industrial Example:

Harvest of Mammalian Cell Cultivations

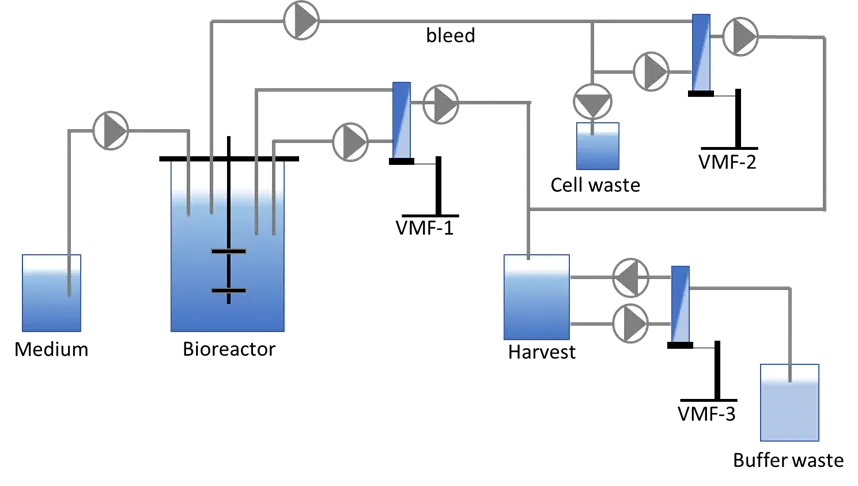

The Vibro® technology in the following example is applied at a Danish biopharma customer, for the critical solid/liquid separation following cultivation.

Description:

Vibro® technology has proved to be an effective means of cell removal from cultivation broth, both in microbial and mammalian processes.

The continuous cleaning effect of the vibrating membrane allows for high flux and the wide offering of membrane materials offer the possibility of optimization of product transmission tailored to the individual cultivation process. Compared to dead-end filtration, Vibro® filtration also increases efficiency by enabling diafiltration.

Mammalian cells, such as CHO, which are considered to be especially fragile, can be retained without indications of cell damage, decrease in viability or release of Host Cell Proteins during filtration procedures of up to 8 hours.

Other applications of Vibro® Technology besides harvest in bioreactors include:

- Cell retention device in perfusion processes

- Recovery of product from perfusion bleed streams

- Ultrafiltration of harvest material to reduce volume before further processing.

Read more about filtration technology

Filtration of biologics

Continuous/perfusion processes

Use of VMF as perfusion device to retain cells in the bioreactor and to harvest API in the permeate from VMF1.

Use of VMF to treat bleed stream by harvesting API and removing up concentrated cells with less API loss.

Harvest/API can be up-concentrated using VMF and remove HCP and impurities to extend capture/Z1 column capacity and lifetime.

Similar setup can be applied to other cell-based applications (cultivated meat, cell therapy, etc.)

Read more about filtration technology

From lab scale to production, we serve you all the way

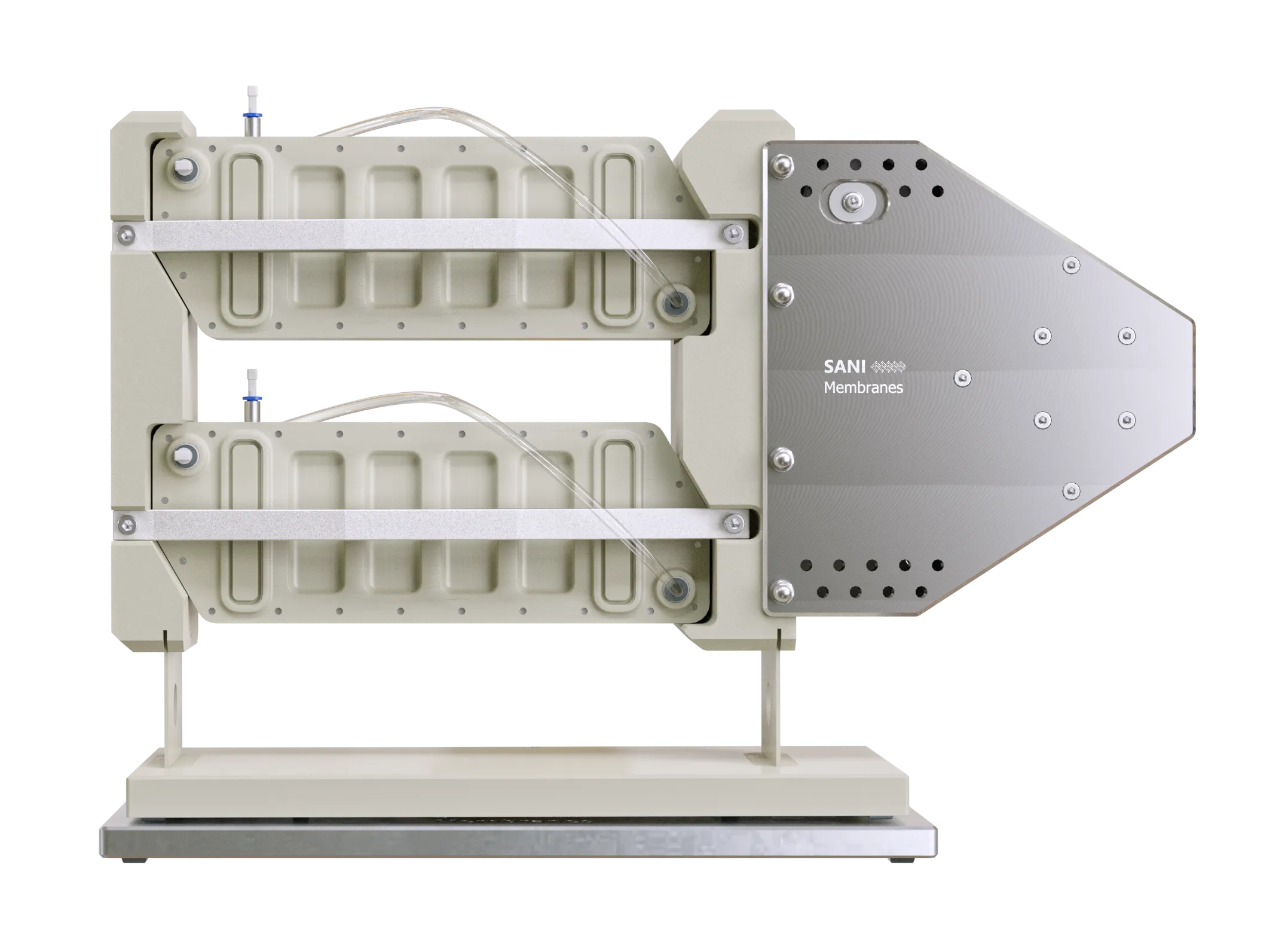

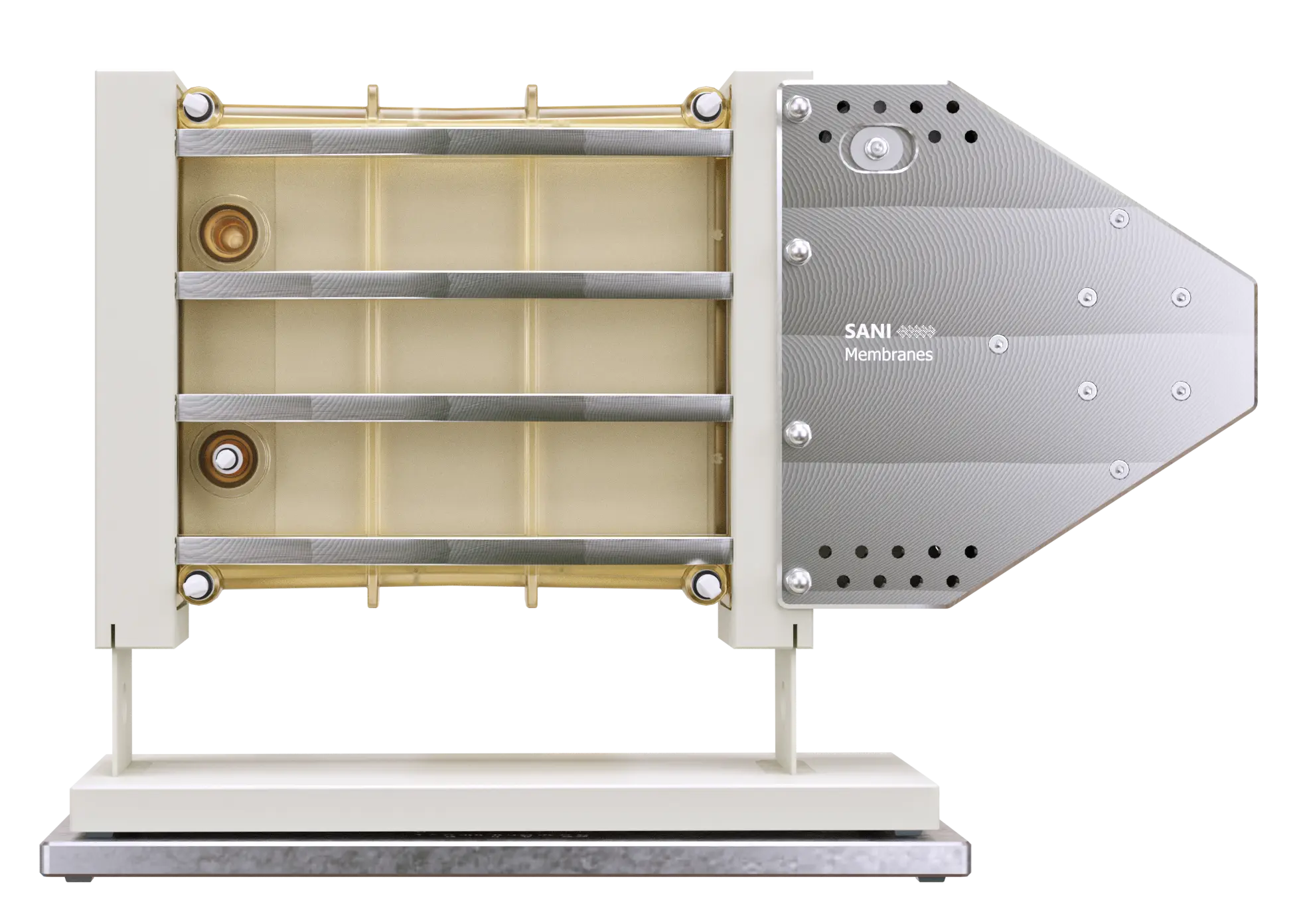

Vibro-Lab35P

Process development with extremely low volumes

Vibro-Lab3500

Improved process development – transparent and scalable

Request demo

Fill in your contact information if you are interested in learning more about Vibro technology.

When filling in the data form, you accept receiving digital communications from SANI Membranes. In order to withdraw your acceptance, please contact info@sanimembranes.com